PURlogic® Flex 1-C gun foam

1C gun foam PURLOGIC Flex

GUNFM-1C-PURLOGICFLEX-750ML

Register and access more than 75 000 products

Recommended by experts and leading window manufacturers

Extremely high elasticity

- Extremely flexible, thereby significantly preventing the risk of a break in the foam bead. (Approx. 3 times the flexibility of commercially available PU foams).

- Prevents heat bridges

Suitable for use in winter

- Down to -15°C surface and ambient temperature

- Down to 0°C can temperature

- Even elastic at minus temperatures

Tested product characteristics

- Component testing

- Joint sound insulation

- Thermal conductivity

- Air permeability

- Water vapour permeability

- Tested energy-saving properties

- General test certificate from construction authorities

- EMICODE-certified

Fine-celled and uniform foam structure

Resistant to ageing

High degree of emptying

Our products featuring the EMICODE label are low emission/environmentally compatible. The EMICODE classification system awards labels to construction products that comply with the very stringent health and environmental requirements of recognised institutes.

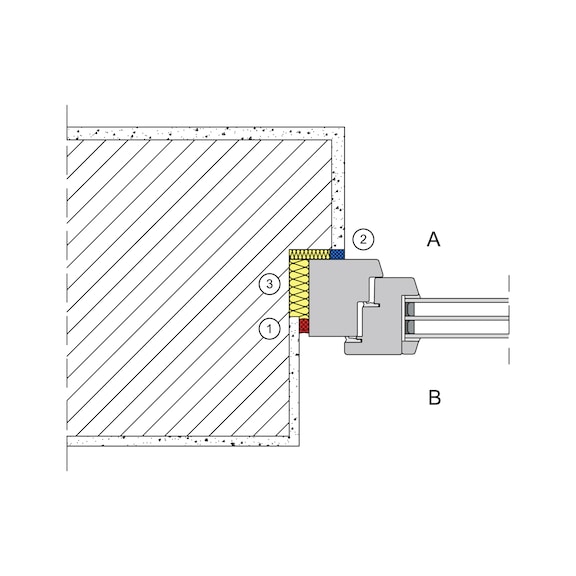

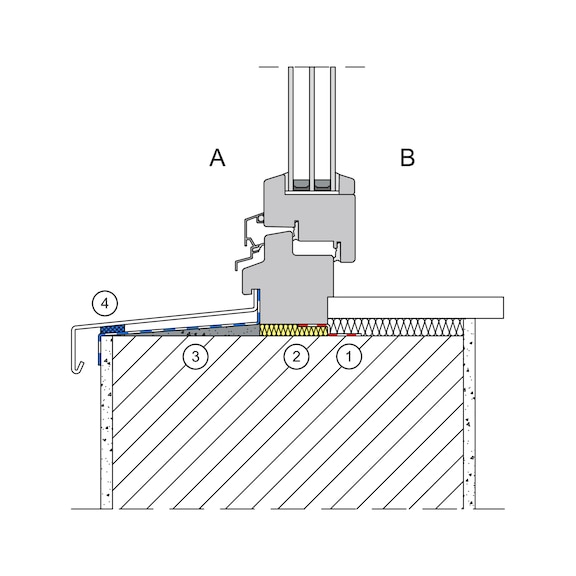

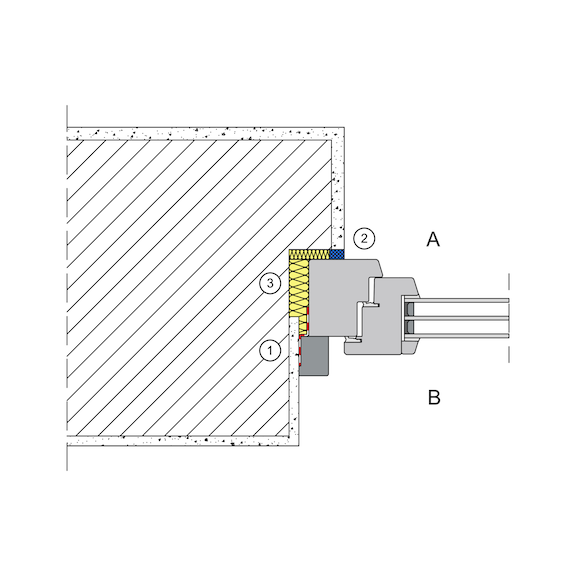

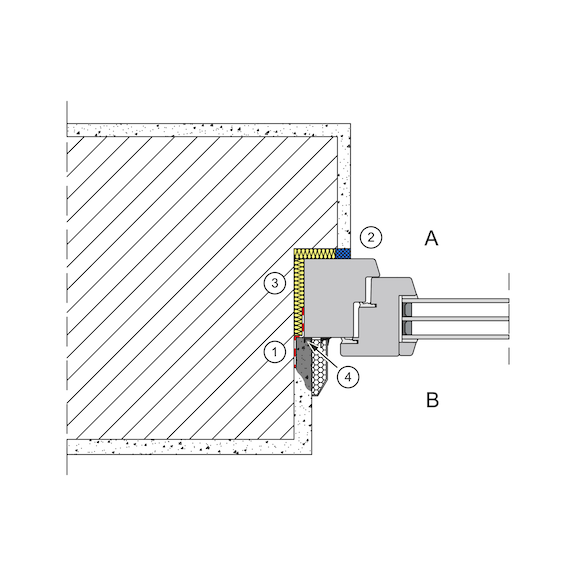

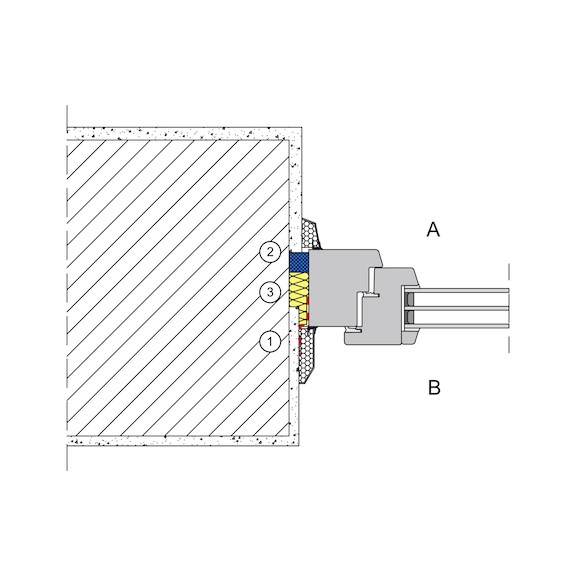

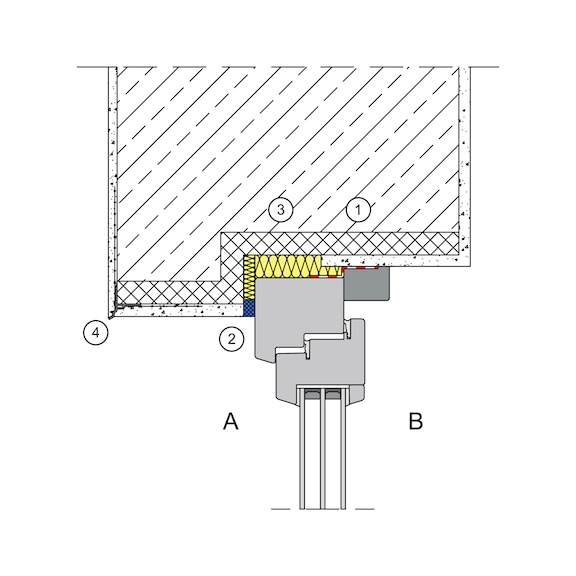

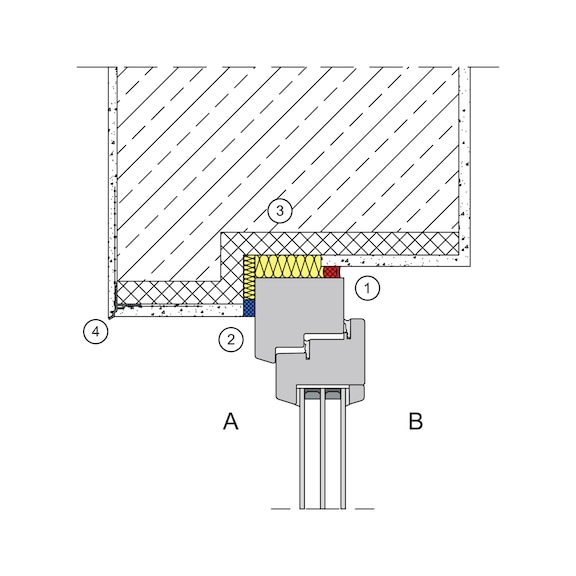

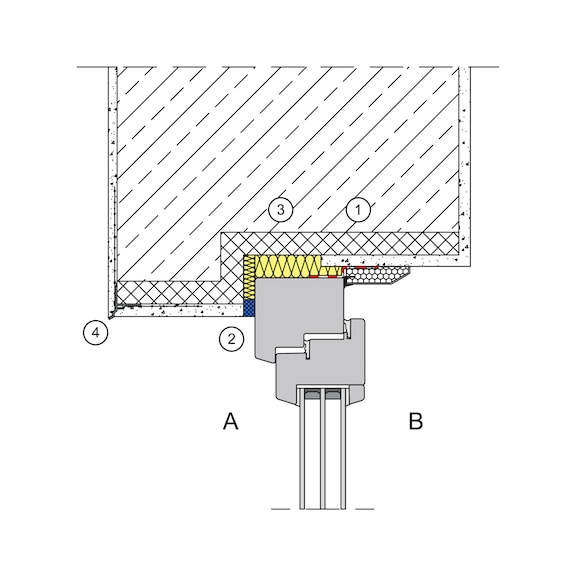

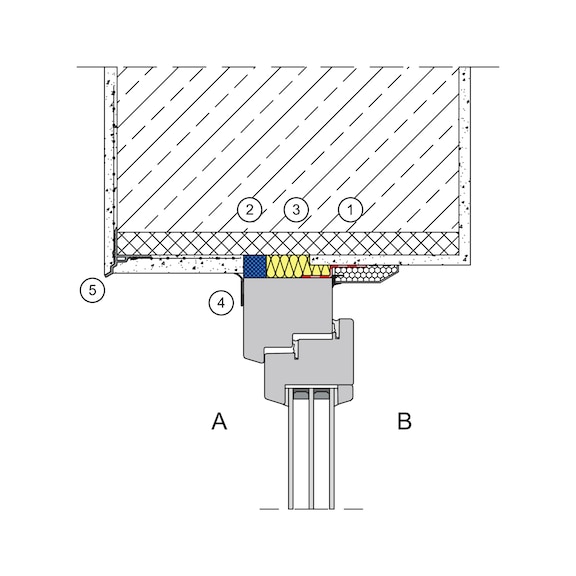

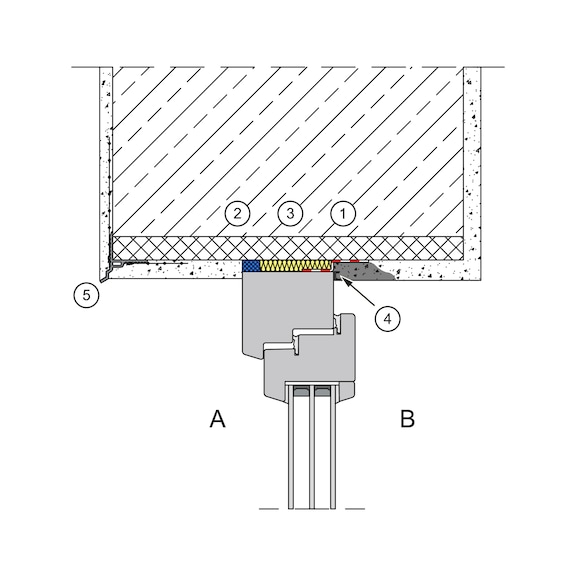

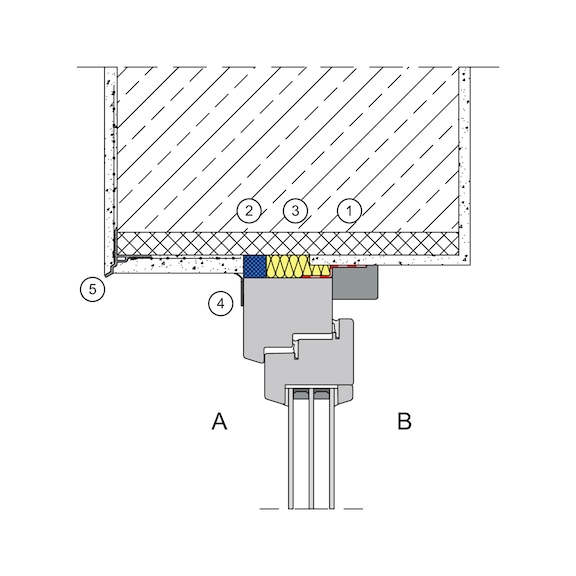

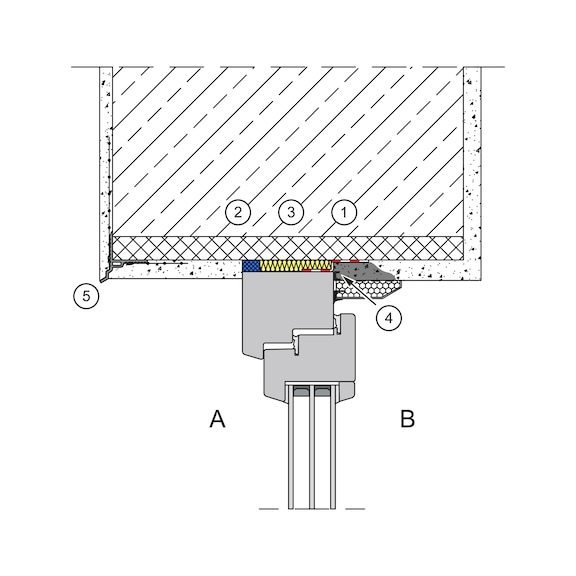

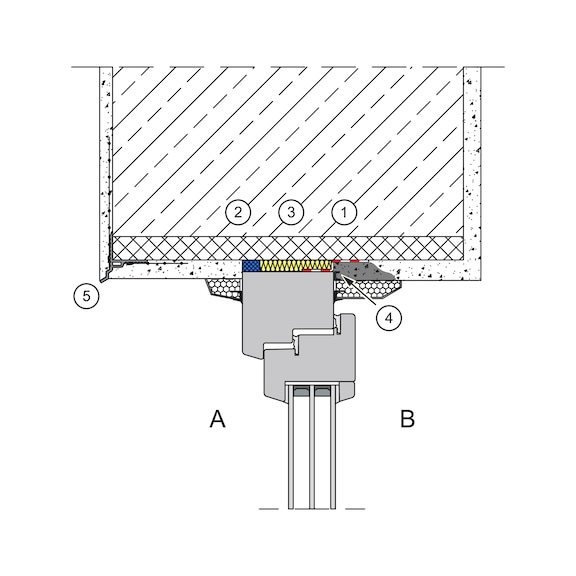

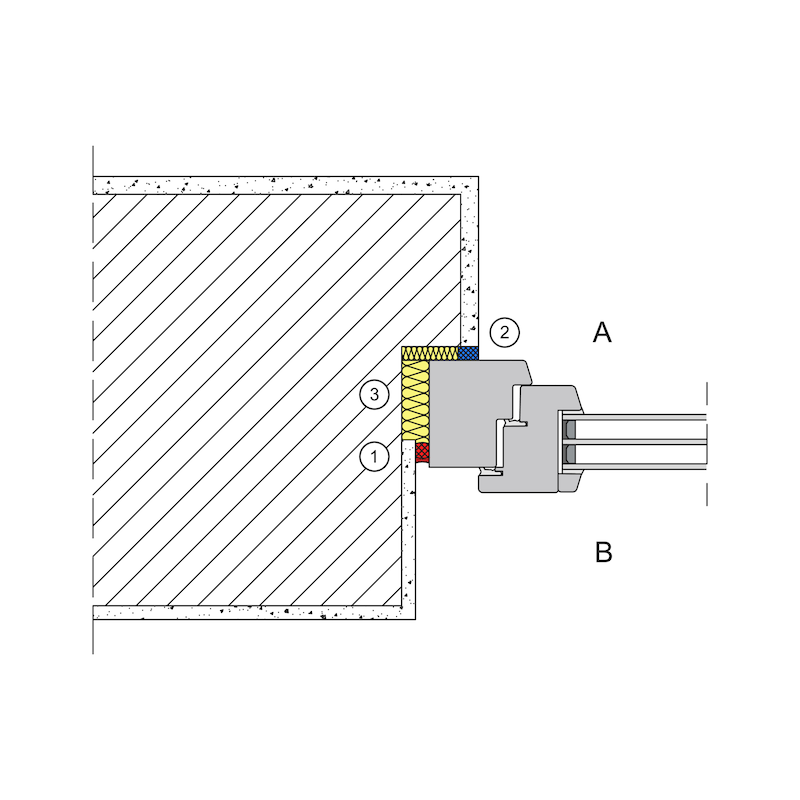

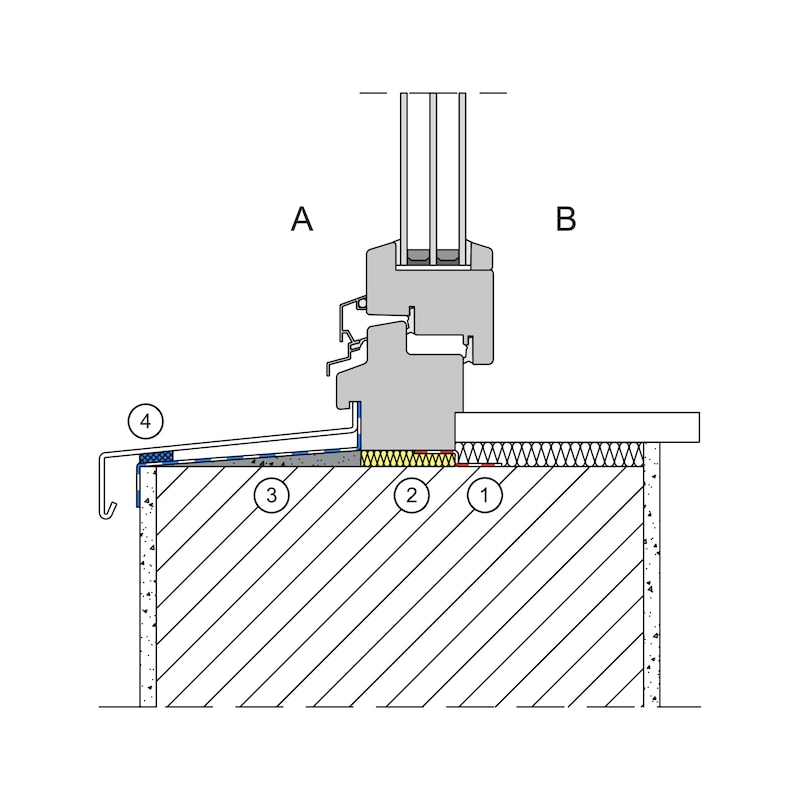

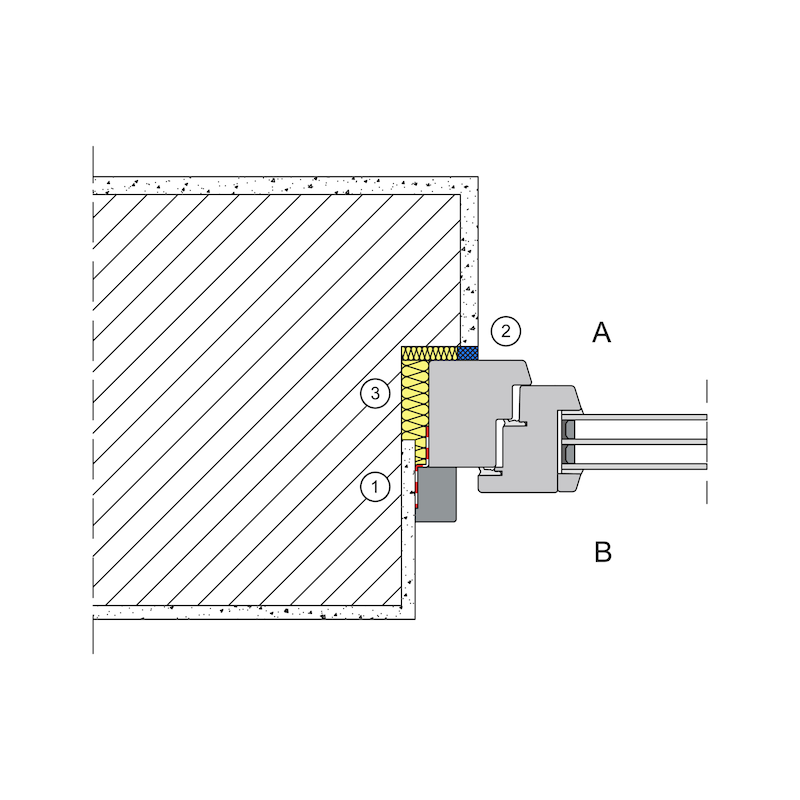

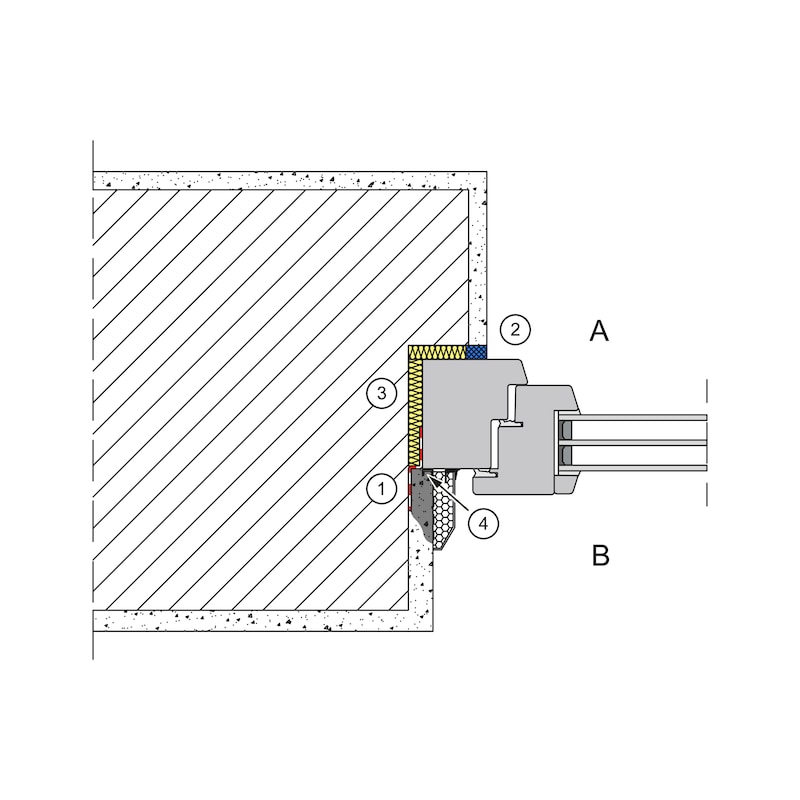

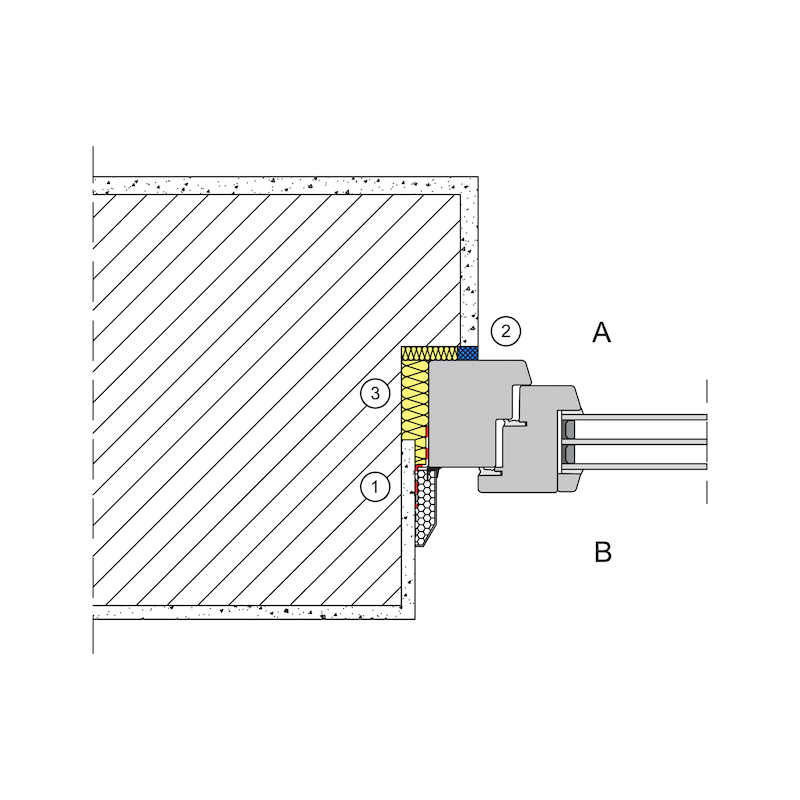

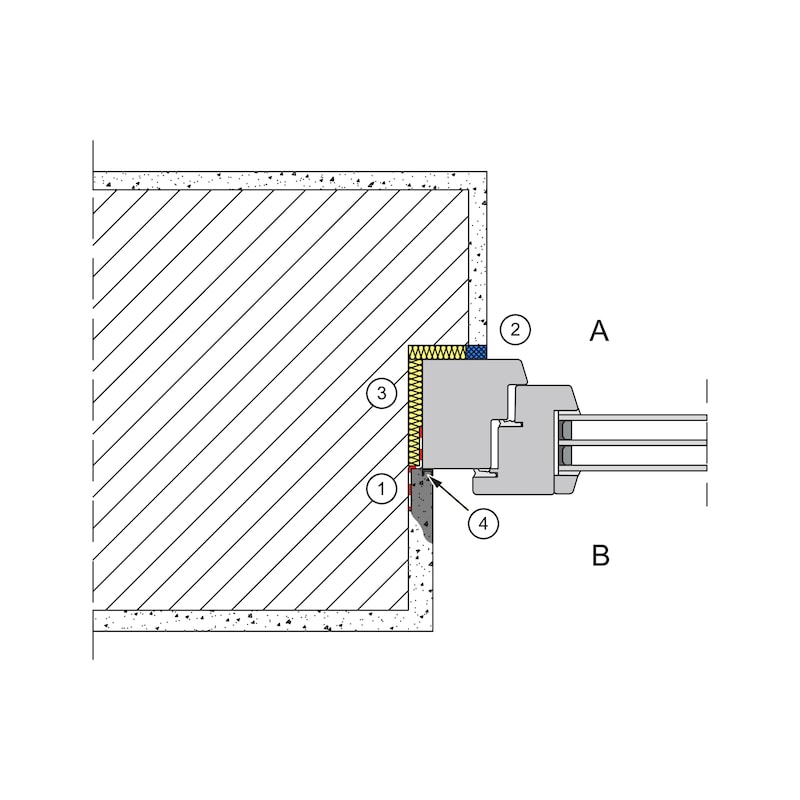

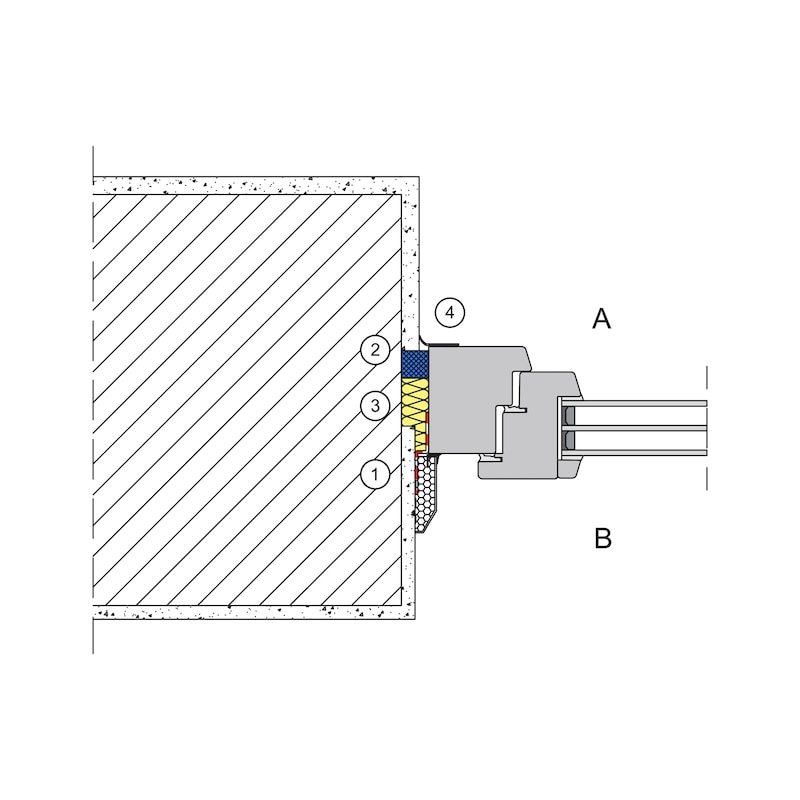

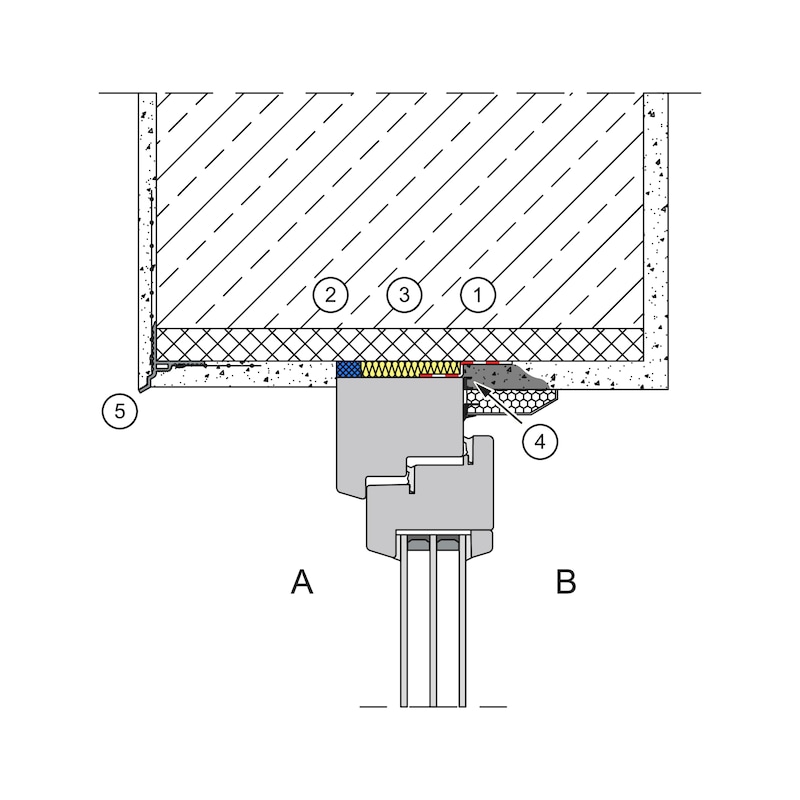

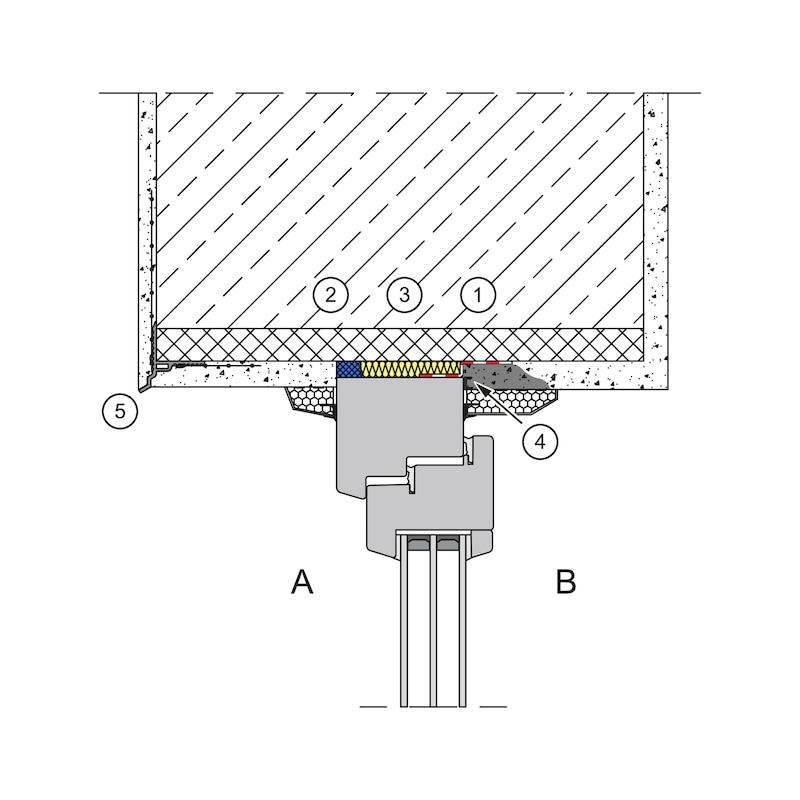

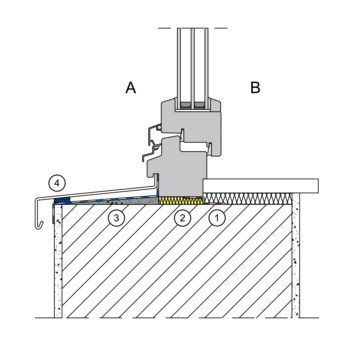

Meets RAL requirements for middle layer insulation.

Adheres to concrete, stone, hard PVC, metal and wood. Does not adhere to polyethylene, silicone, PTFE and grease. PURLOGIC FLEX can be applied with PURLOGIC Xpress and PURLOGIC. Primer should be applied to porous and absorbent substrates. Unhardened foam must not come into contact with wet adhesive.

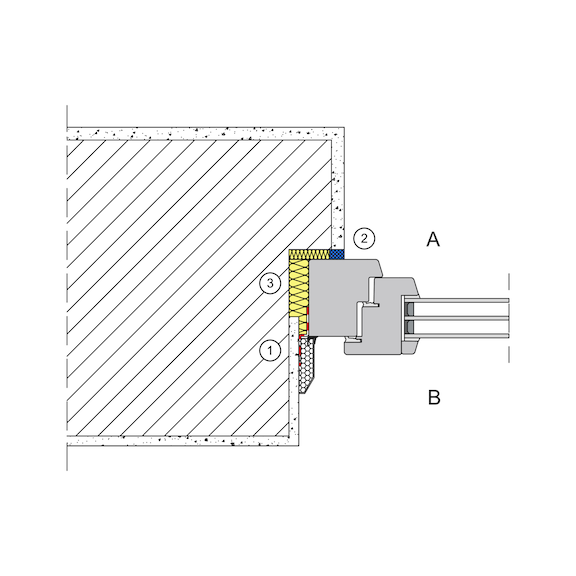

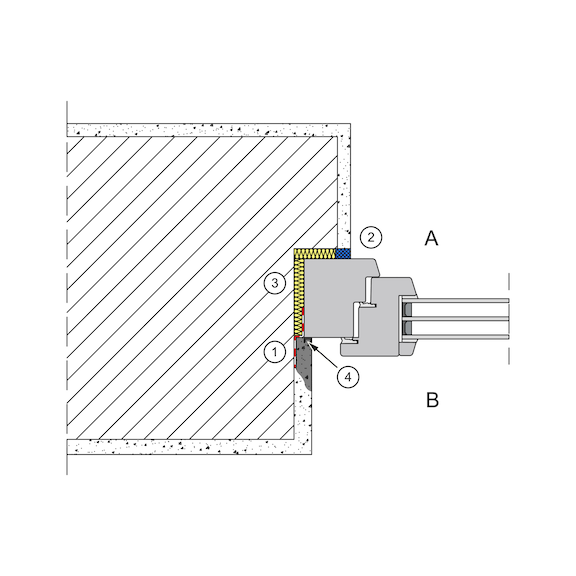

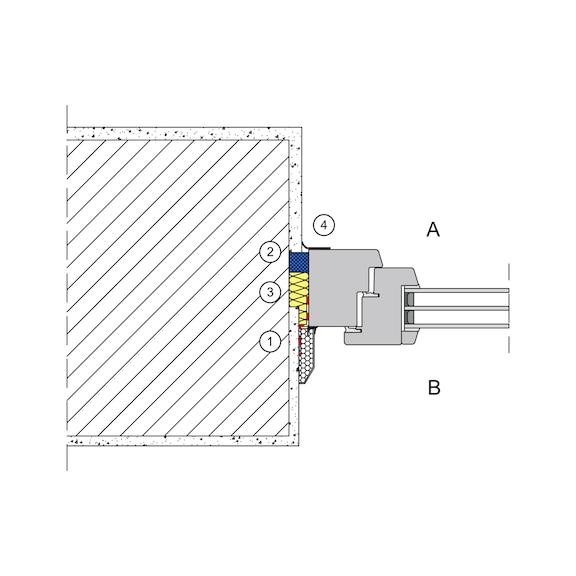

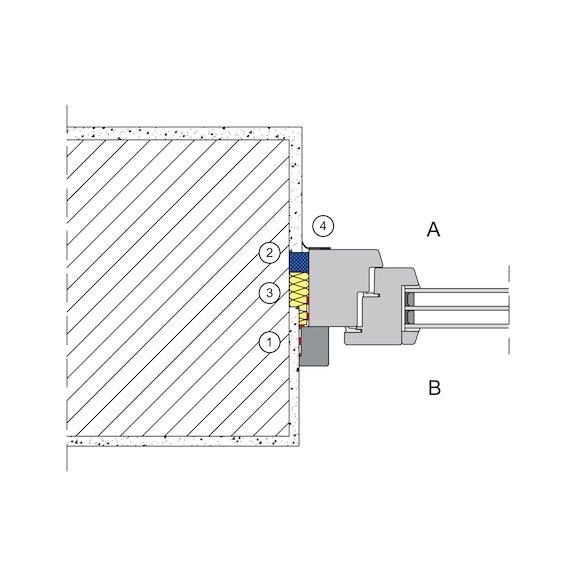

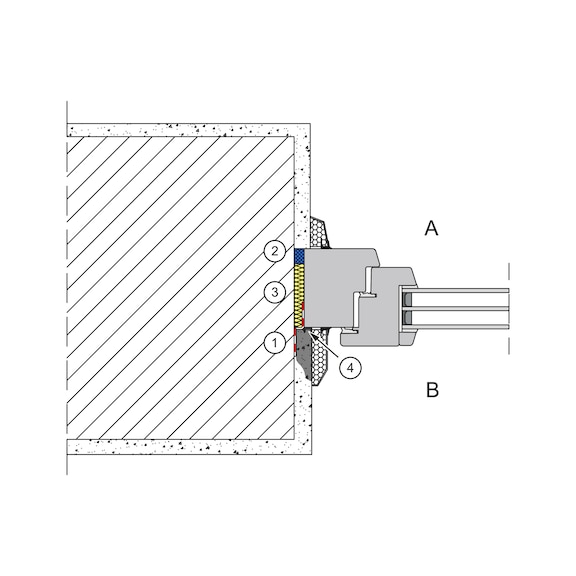

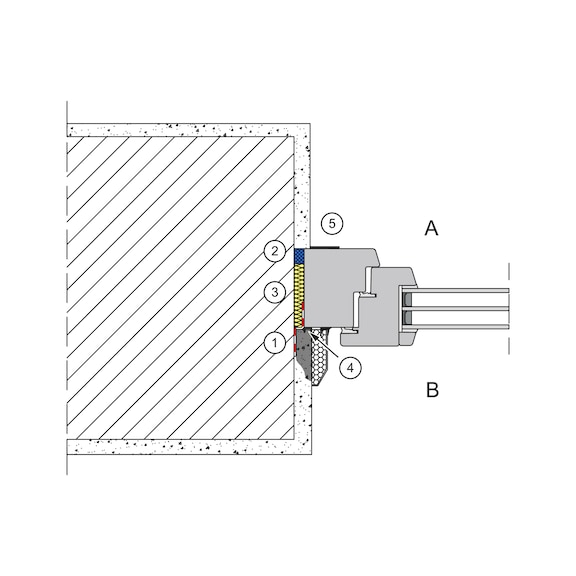

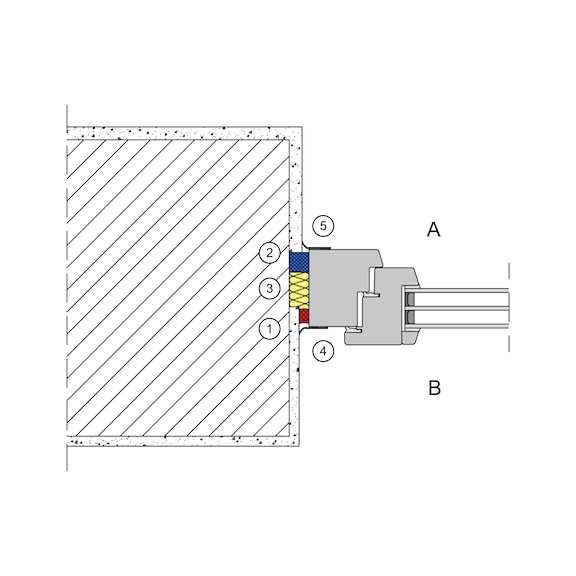

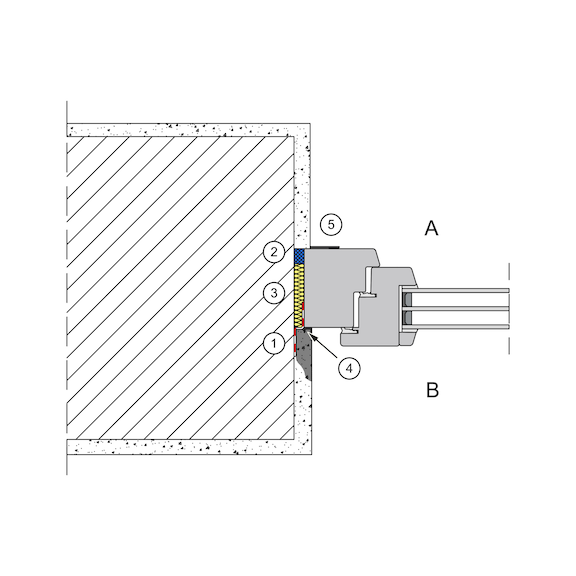

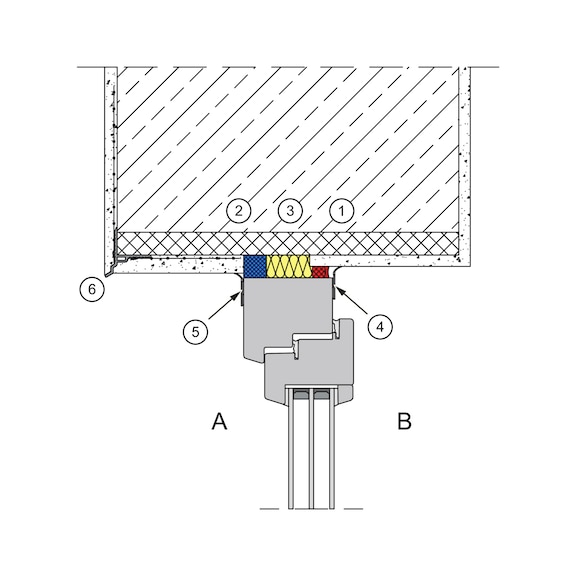

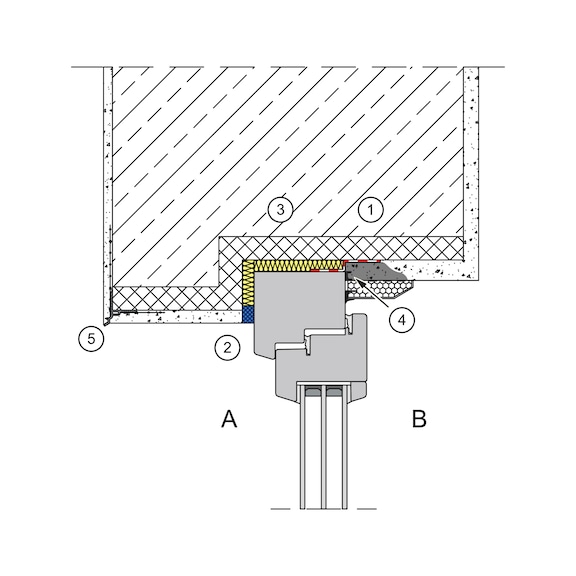

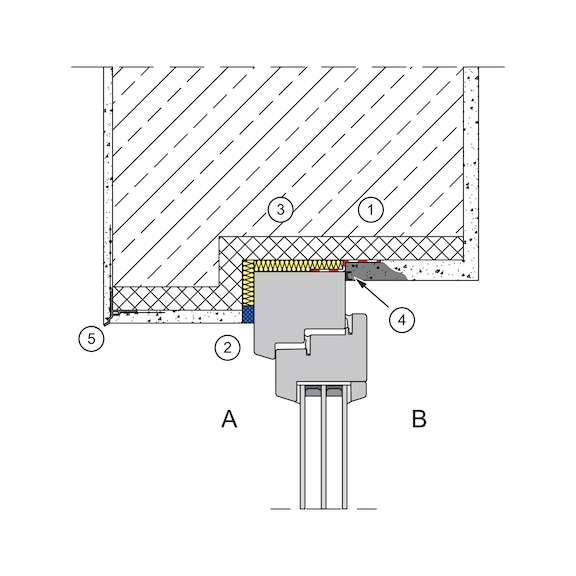

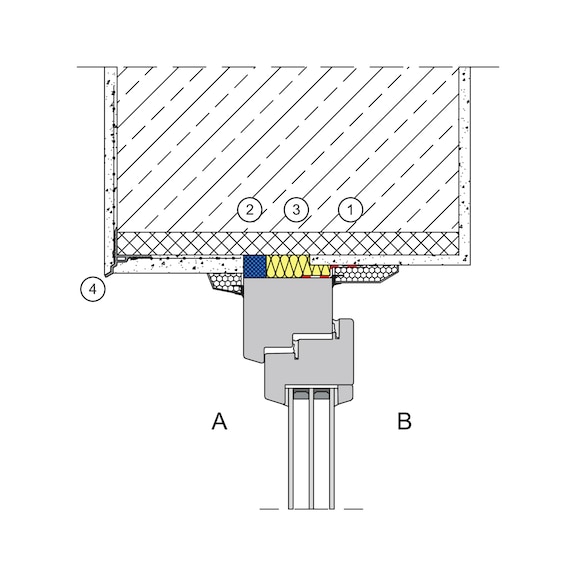

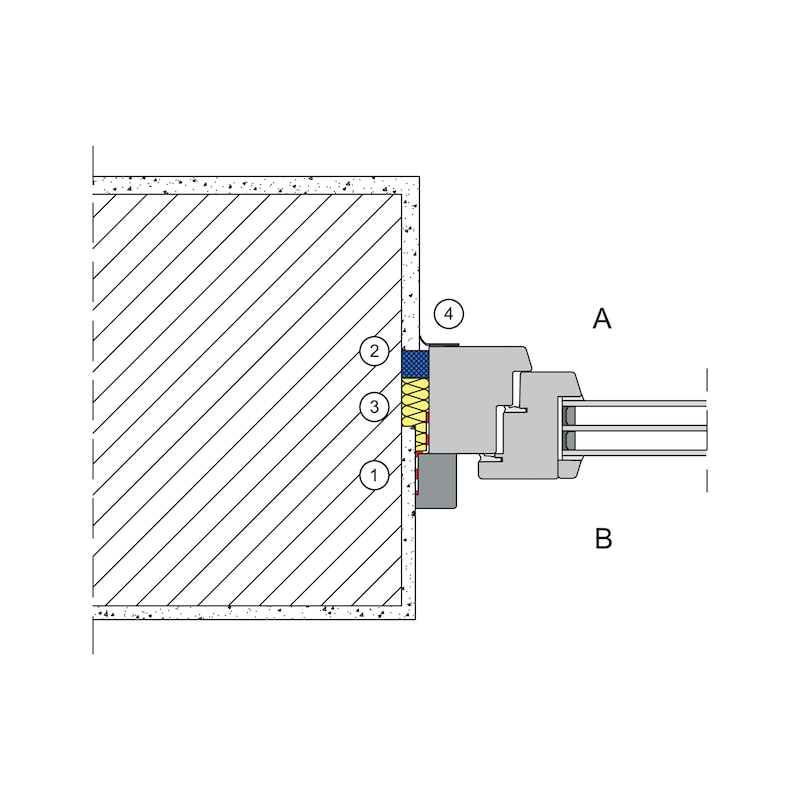

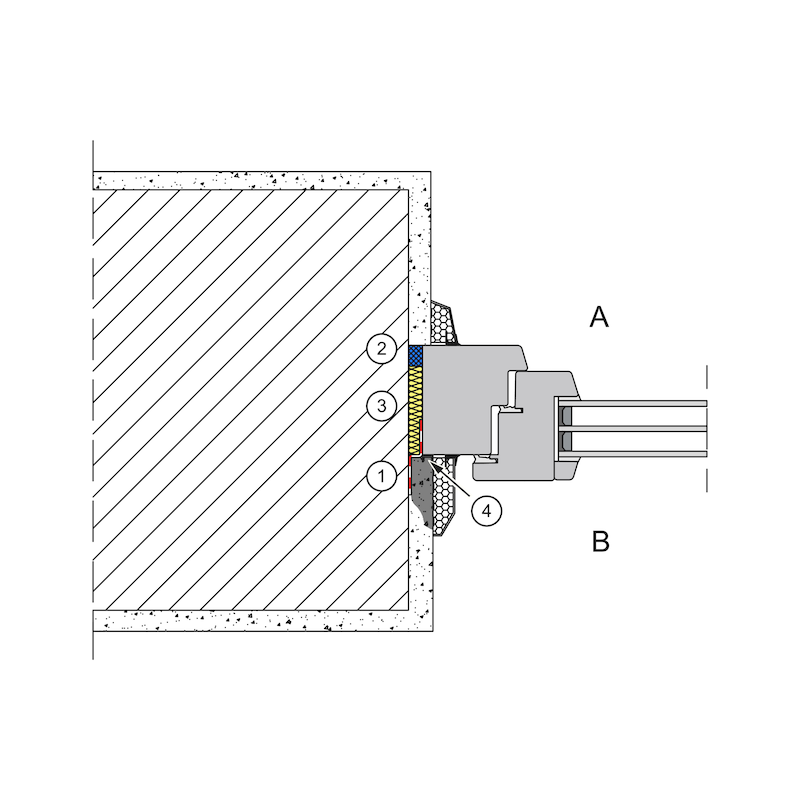

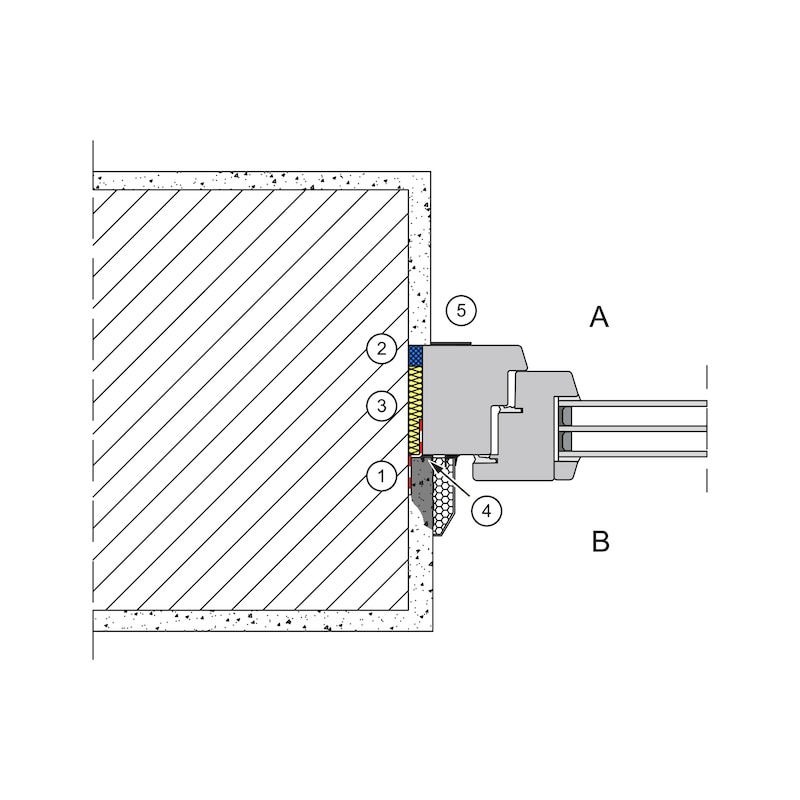

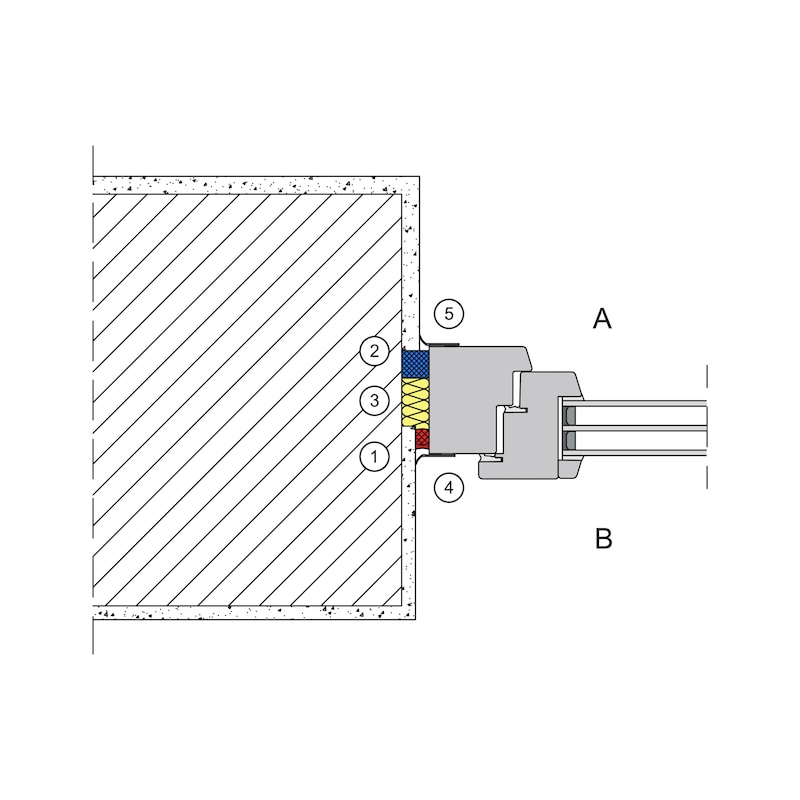

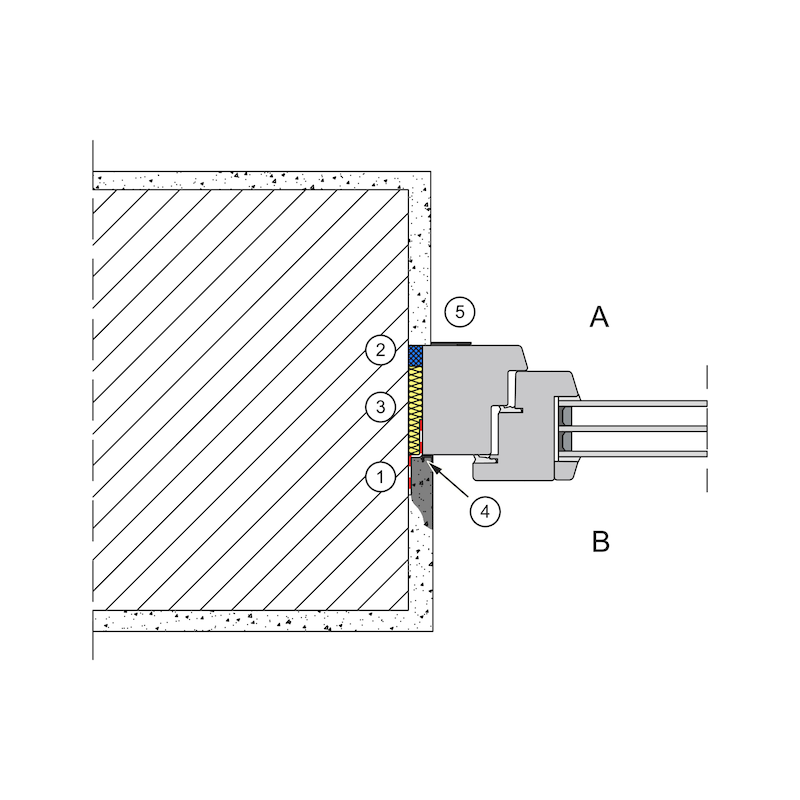

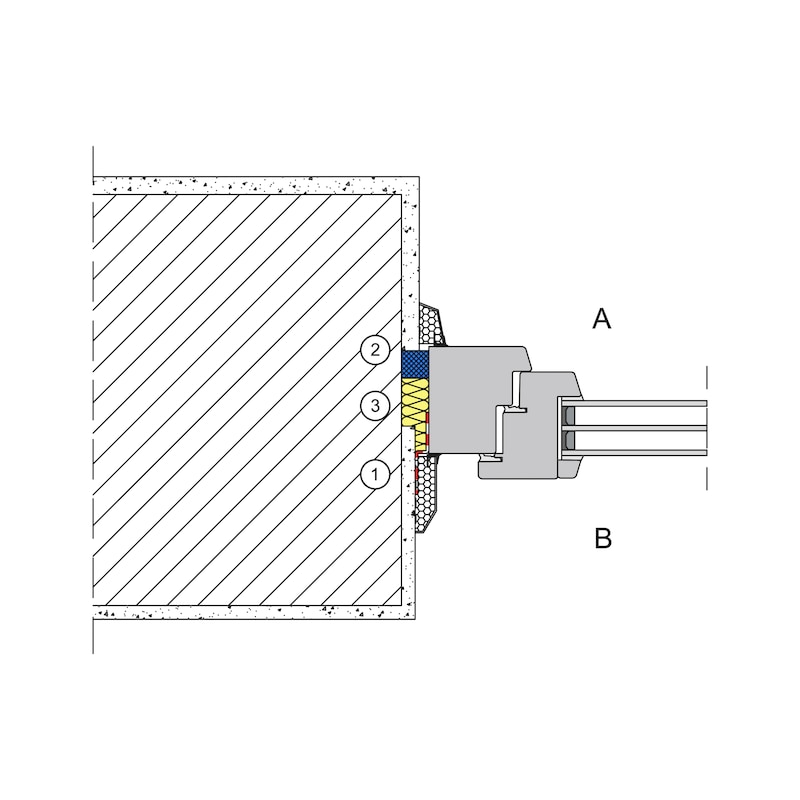

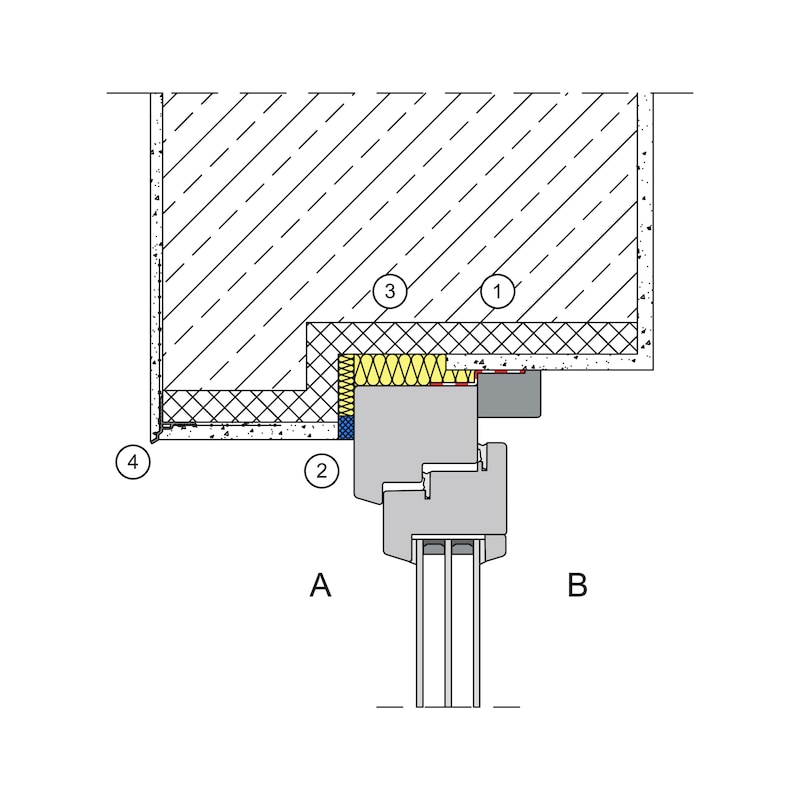

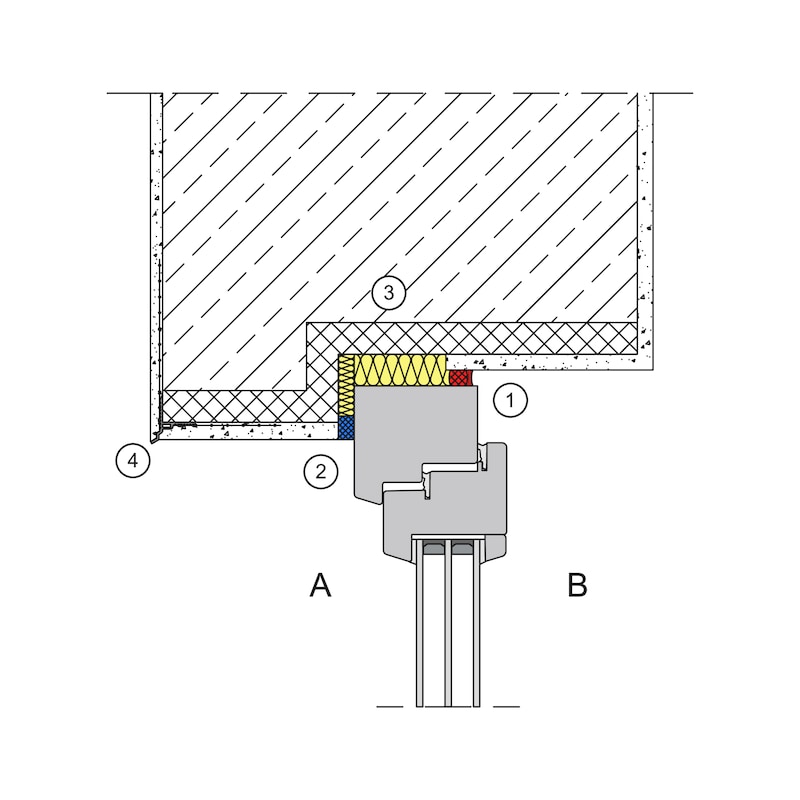

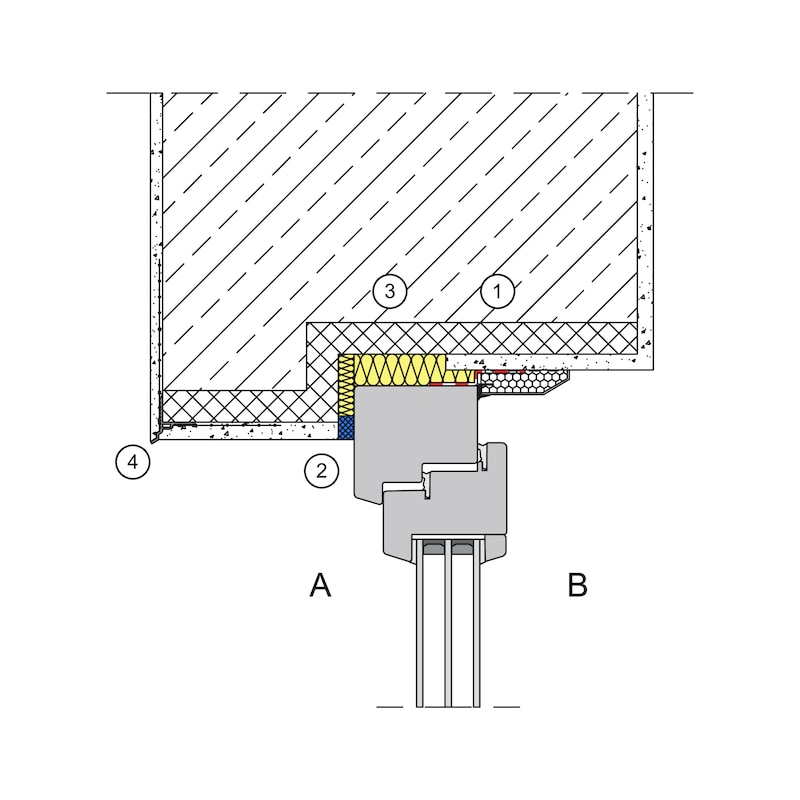

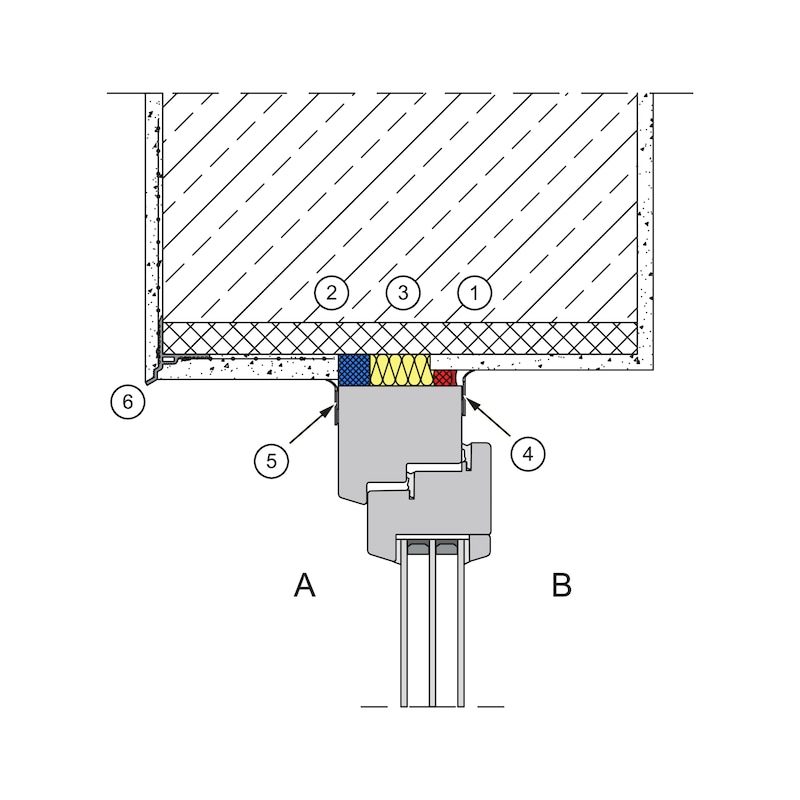

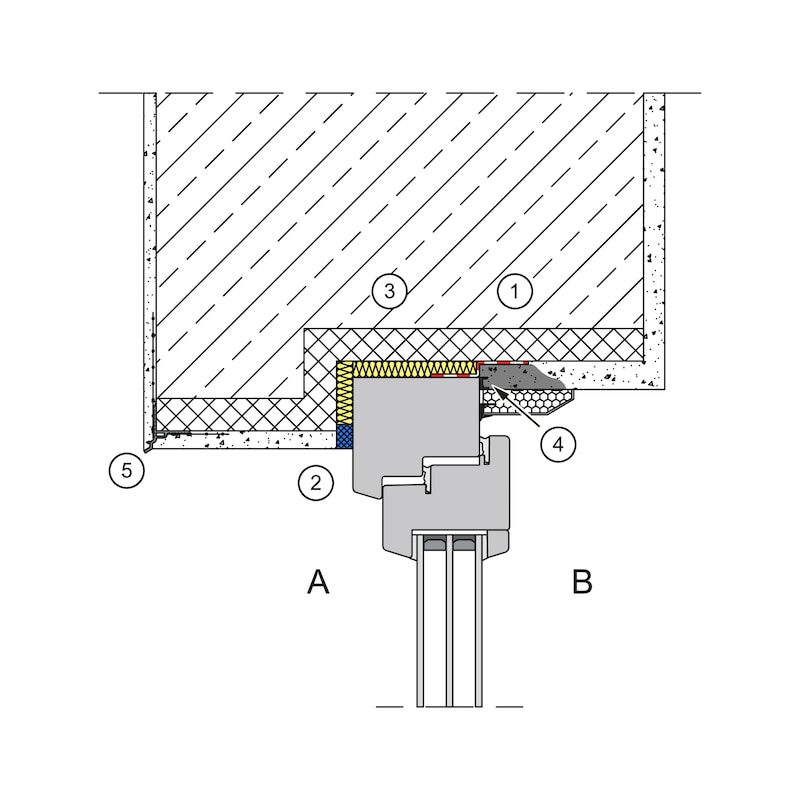

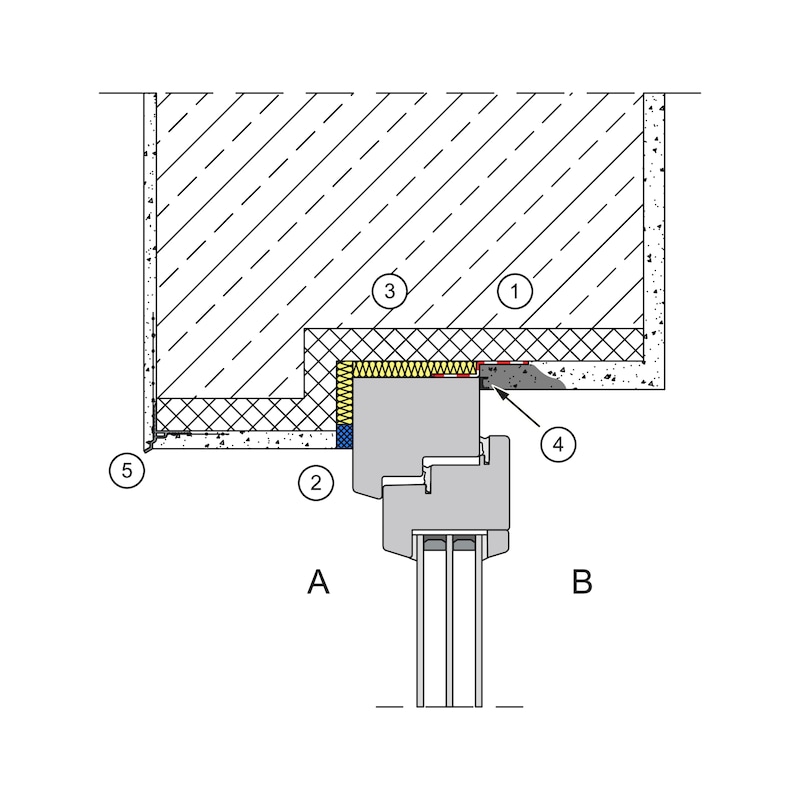

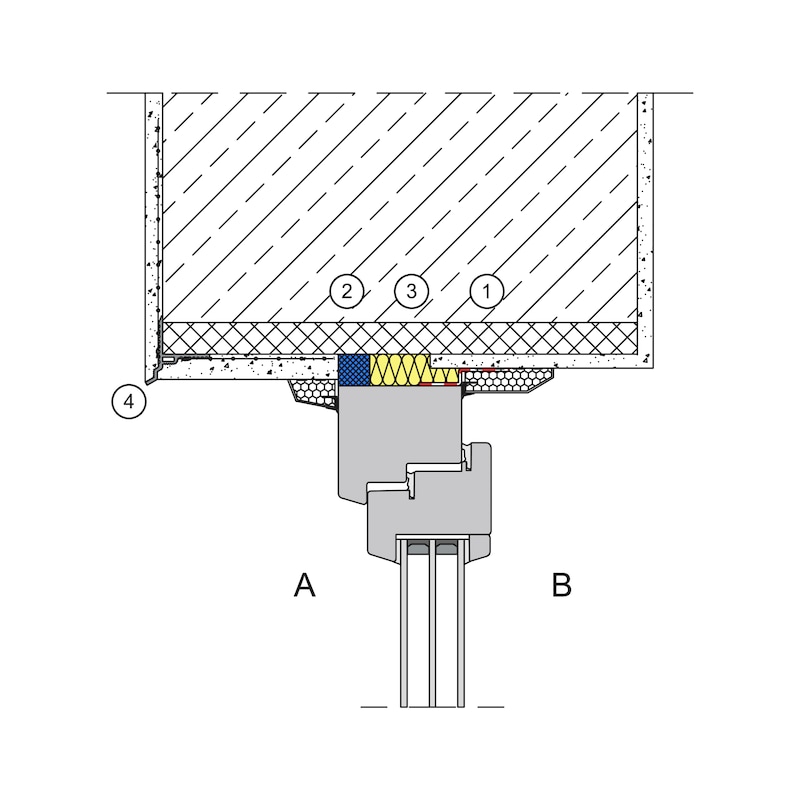

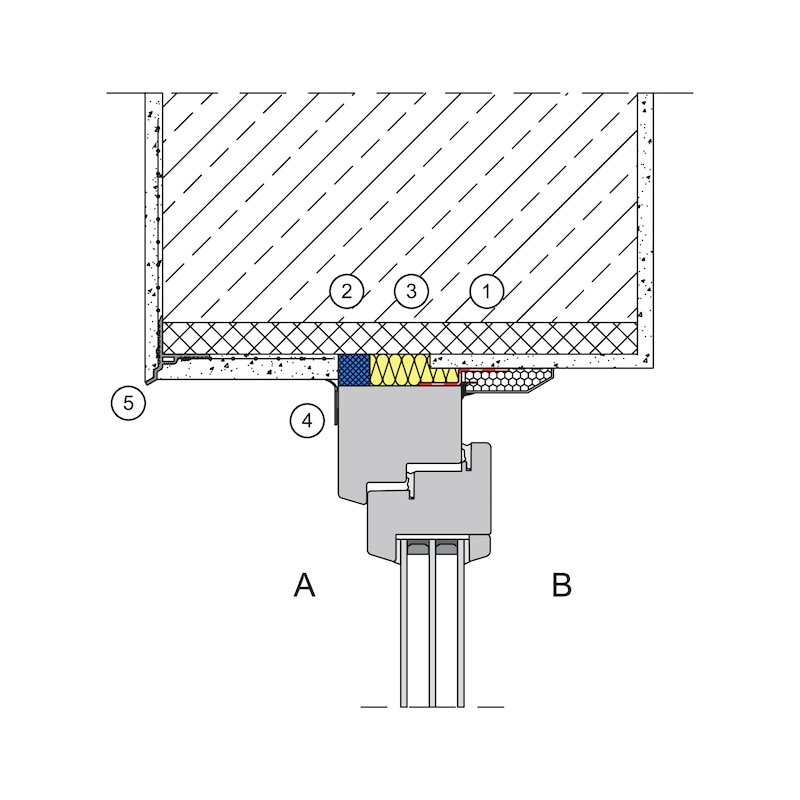

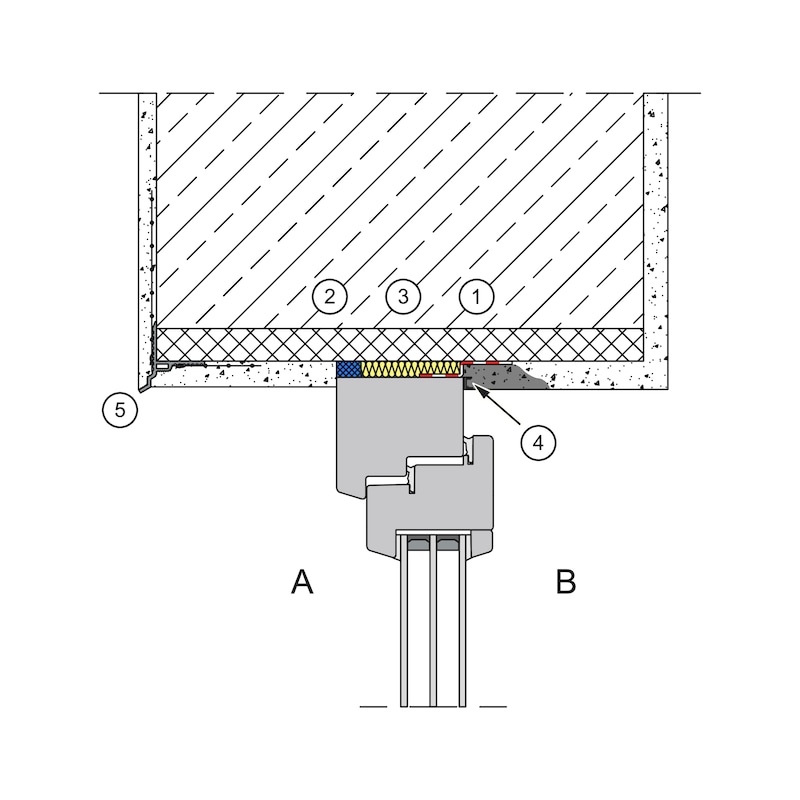

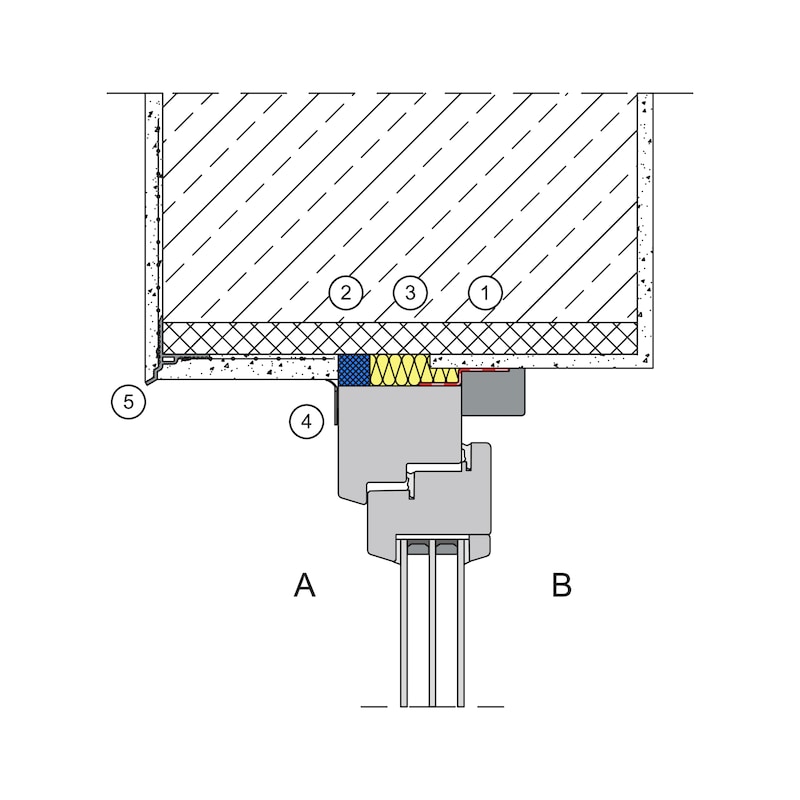

Perimeter sealing systems according to ift certification programme QM360: 2014, Reg. no. 188 7050098

EMICODE EC1plus: Very low emissions: The EMICODE classification system distinguishes the environmental and health compatibility of construction products. The lowest-emission products bear the EC1plus mark.

The usage instructions are recommendations based on the tests we have conducted and our experience; carry out your own tests before each application. Due to the large number of applications and storage and processing conditions, we do not assume any liability for a specific application result. Insofar as our free customer service provides technical information or acts as an advisory service, no responsibility is assumed by this service except where the advice or information given falls within the scope of our specified, contractually agreed service or the advisor was acting deliberately. We guarantee consistent quality of our products. We reserve the right to make technical changes and further develop products.

Datasheets(X)

For insulating and filling window joints, pipe openings, wall openings, wall joints, cavities, refrigerated trucks, walk-in refrigerators, roof finishing, roller shutter boxes and window sills.

Shake can vigorously 20 times before use. Surfaces must be clean, solid and free from dust and grease. Prime highly absorbent substrates. Adhesion surfaces must be moistened with water before the foam is applied. Moisten again if several foam beads are applied. Screw the can all the way into the gun support - do not screw too far or tilt. Foam continues to expand after application. Immediately remove splashes of foam with PURLOGIC CLEAN, art. no. 0892 160. Thoroughly clean the gun and valve after use. If you need to interrupt your work, leave the can attached and turn the dosing screw all the way to close and seal the gun. If the gun is not intended to be used for a prolonged period of time, it needs to be rinsed as follows: Quickly screw the PU foam cleaner with the screw adapter onto the gun. Actuate the outlet until clear liquid comes out. In addition, carefully remove foam residue from the outside of the gun using PU foam cleaner. The contents of the can must be used within 4 weeks.

| |

Chemical basis | Polyurethane |

Colour | Grey |

Smell/fragrance | Characteristic |

Moulded density | 24 kg/m³ |

Cell structure | Medium - fine |

Cell structure conditions | tested in accordance with Würth test methods |

Tack-free after | 6 min |

Conditions for being tack-free | at 23°C and 50% humidity |

Can be cut after | 20 min |

Conditions for ability to cut | at 23°C and 50% relative humidity |

Full resilience | 12 h |

Conditions for full resilience | at 23°C and 50% relative humidity |

Min. processing temperature | 5 °C |

Max. processing temperature | 25 °C |

Min. ambient processing temperature | -15 °C |

Max. ambient processing temperature | 25 °C |

Min. surface processing temperature | -15 °C |

Max. surface processing temperature | 25 °C |

Min. processing temperature for can | 0 °C |

Min. temperature resistance | -40 °C |

Max. temperature resistance | 90 °C |

Building material class | B2 - Normally inflammable |

Building material class conditions | in accordance with DIN 4102 |

Heat conductance λ | 0.035 W/(m*K) |

Compression strength | 5 N/cm² |

Compression strength conditions | in accordance with DIN 53421 |

Min. tensile strength | 5 N/cm² |

Acoustic insulation for joints | 60 dB |

Conditions for acoustic insulation of joints | with 10-mm and 20-mm wide joint |

Ultraviolet resistance | No |

Shear strength | 3 N/cm² |

Yield (volume) approx. | 27 l |

Contents | 750 ml |

Container | Aerosol can |

Weight of content | 872 g |

HCFC-free | Yes |

CFC (fuel gas) free | Yes |

FC-free | Yes |

HFC-free | Yes |

Shelf life from production | 12 Month |

Conditions to maintain shelf life from production | at 20°C |

Sustainability | Low-emission/low-pollution |

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!