Chemical injection mortar Concrete Multi WIT-UH 300

Chem. injection mortar Concrete Multi WIT-UH 300

ANC-MORT-(WIT-UH300)-CART-420ML

Register and access more than 75 000 products

- Two-component reactive resin mortar, urethane vinyl ester hybrid mortar, styrene-free

- Individual fixing point in cracked and uncracked concrete, seismic performance category C1 (M8 to M30) and C2 (M12 to M24): Anchor rod W-VI-A, anchor rod W-VD-A, standard threaded rod with acceptance test certificate 3.1, female thread anchor W-VI-IG

- Areas subject to the German Federal Water Act (Wasserhaushaltsgesetz - WHG): Würth injection system WIT-UH 300 (bonded anchor) for use in uncoated LI/LIP concrete surfaces in SFH facilities

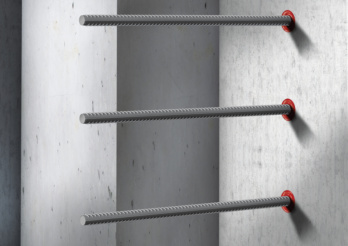

- Post-installed rebar connection

- European Technical Assessment ETA-17/0127: Individual fixing point + cracked and uncracked concrete (anchor rod W-VI-A, anchor rod W-VD-A, standard threaded rod with acceptance test certificate 3.1, female thread anchor W-VI-IG), seismic performance category C1 (M8 to M30) and C2 (M12 to M24)

- European Technical Assessment ETA-17/0036: Post-installed rebar connection (REBAR)

- European Technical Assessment ETA-23/0699: Post-installed rebar connection with improved bond and splitting failure when subjected to static action

- General type approval Z-74.8-207: Würth WIT-UH 300 injection system for use in uncoated LI/LIP concrete surfaces in SFH facilities (anchorage in sealing surfaces subject to the German Federal Water Act)

- General type approval Z-21.8-2156: Post-installed rebar connection subject to fatigue-inducing action

We recommend the Würth Technical Software for planning and dimensioning your assembly.

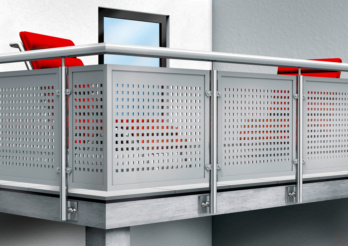

Fastening of railings

Fastening of railings

Wooden structures

Wooden structures

Post-installed rebar connection (REBAR)

Post-installed rebar connection (REBAR)

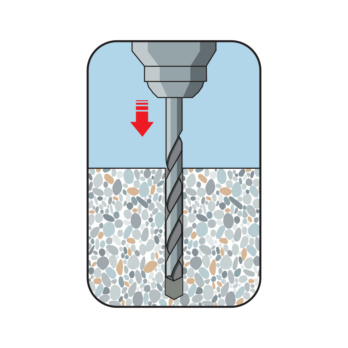

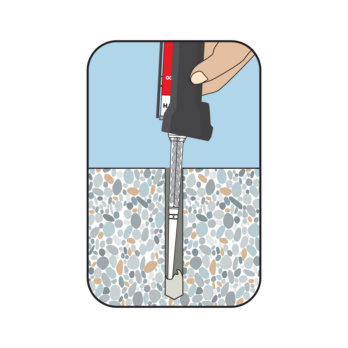

Drill the hole

Make the drill hole using Würth hollow drill bit, there is no need for hole cleaning

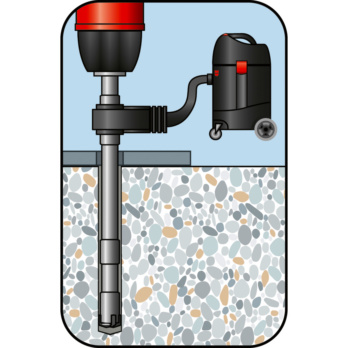

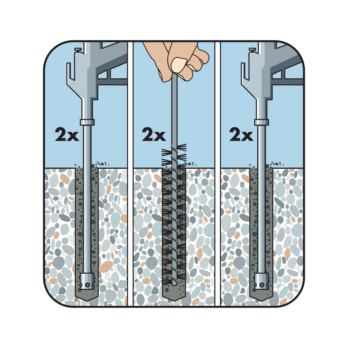

Clean the drill hole:

Blow out 2x with oil-free compressed air (min. 6 bar)/brush out 2x/blow out 2x with oil-free compressed air (min. 6 bar)

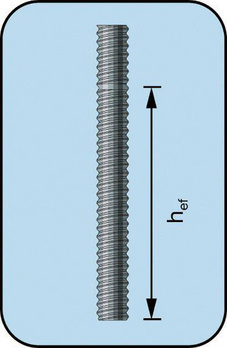

Cut anchor rod to length and mark the desired insertion depths

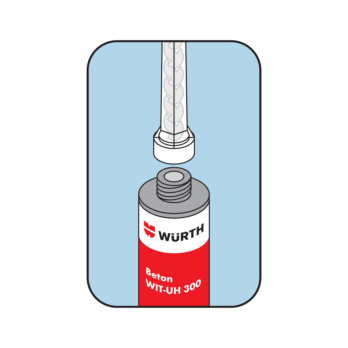

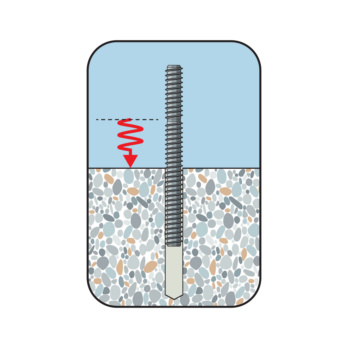

Screw mixer onto cartridge

Discard the first section of mortar (until the mortar is uniformly coloured - approx. 10 cm)

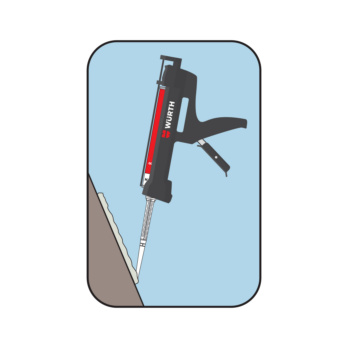

Fill injection mortar starting from base of drill hole

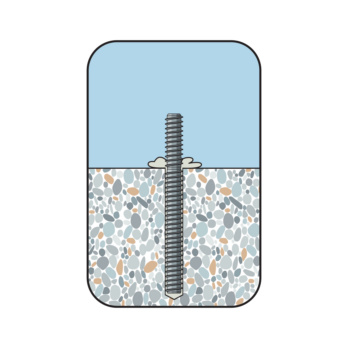

Press in anchor rod up to drill hole base while turning slightly

Visual check of mortar volume, embedment depth mark

Observe the injection mortar curing time

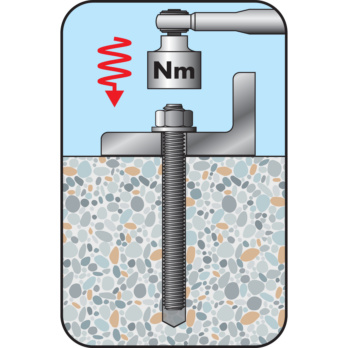

Install component, apply installation torque

- European Technical Assessment ETA-17/0127: Individual fixing point + cracked and uncracked concrete (anchor rod W-VI-A, anchor rod W-VD-A, standard threaded rod with acceptance test certificate 3.1, female thread anchor W-VI-IG), seismic performance category C1 (M8 to M30) and C2 (M12 to M24)

- European Technical Assessment ETA-17/0036: Post-installed rebar connection (REBAR)

- European Technical Assessment ETA-23/0699: Post-installed rebar connection with improved bond and splitting failure when subjected to static action

- General type approval Z-74.8-207: Würth WIT-UH 300 injection system for use in uncoated LI/LIP concrete surfaces in SFH facilities (anchorage in sealing surfaces subject to the German Federal Water Act)

- General type approval Z-21.8-2156: Post-installed rebar connection subject to fatigue-inducing action

- Suitable for fastening metal structures, metal profiles, wooden structures, brackets, pipes, cable conduits etc.

- Suitable for structural expansions, ceiling and wall outlets, expansion of load-bearing structures, reinforcement of load-bearing structures, attachment of balconies and canopies, sealing of temporary openings and "forgotten" reinforcing bars

- Fastening system for use in collection trays, collection facilities and surfaces made from uncoated LI and LIP concrete in systems for storing, filling and handling substances that are hazardous to water

Type description | WIT-UH 300 |

Container | Coaxial cartridge |

Contents | 420 ml |

Suitable application gun | Battery-powered application gun 420ml, Application gun MULTI, Application gun WIT 420ml, Pneumatic application gun 420ml, EasyMax 420 ml, HandyMax 420 ml |

Min./max. processing temperature /conditions | -5 to 40 °C / temperature in the anchorage ground during processing and hardening |

Min./max. ambient temperature / Conditions | -40 to 160 °C / after completely curing process |

Temperature resistance, long-term temperatures max. | 100 °C |

Temperature resistance, short-term temperatures max. | 160 °C |

Shelf life from production/conditions | 18 Month / cool and dry storage area, 5°C to 25°C |

Approval | ETA-17/0036, ETA-17/0127 |

Chemical basis | Two-component resin |

Colour | Grey |

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!