MIG wire Wurth 2594

MIG welding wire, Super Duplex AWS A5.9:ER2594

WELDWRE-MIG-ER2594-1,0X15KG

Register and access more than 75 000 products

Austenitic ferritic super duplex – solid wire made from stainless 25Cr10Ni-4Mo steel alloy. The wire has high tensile strength and resistance to cracking caused by pitting corrosion and stress corrosion.

It can be magnetised and polished.

Pitting corrosion index PRE =40.

Suitable for welding, combining and coating stainless steels of similar compositions (super duplex and duplex).

- AWS A5.9 ER2594

- EN ISO 14343-A G/W 25 9 4 NL

Classification:

AWS A5.9 ER2594

EN ISO 14343-A G/W 25 9 4 NL

Material no. 1.4501

Shielding gases (according to ISO 14175):

M12 Mixed gas Ar+ 0.>5-5% CO2

M13 Mixed gas Ar+ 0.>5-3% O2

- AWS A5.9 ER2594

- EN ISO 14343-A G/W 25 9 4 NL

Datasheets(X)

Applications: Petrochemical and offshore industry (e.g. sheets, piping), where much higher corrosion resistance is required than can be provided by austenitic stainless steel in environments with high levels of chloride.

Applications: Acid gas industry, transportation of chemical products, pulp and paper industry.

Wire diameter (Ø) | 1.0 mm |

Layer-coiled | Yes |

Weight | 15 kg |

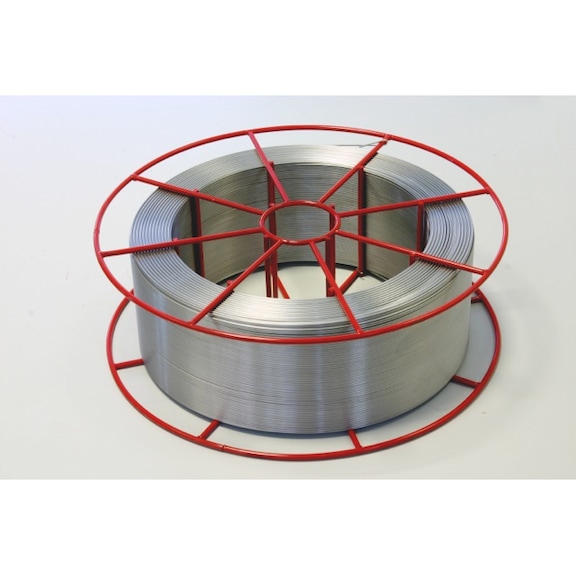

Type of coil | Metal coil BS300, red |

Min. longitudinal elongation | 18 % |

Min. tensile strength | 620 N/mm² |

Product weight (per item) | 15 kg |

Shielding gas | Argon/CO2 |

Mechanical properties, typical, clean welding material | |

| Typical values | |

| Protective gas | M12 |

| 0.2 Yield strength N/mm² | 450 |

| Tensile strength N/mm² | 550 |

| Elongation % | 20 |

| Baton ISO-V(J) +20°C | 50 |

Weldable materials | ||

| Steel quality EN 10088-1/-2 Stainless duplex steels | Material number | UNS |

| X2 CrNiMoN 22-5-3 | 1.4462 | S31803 |

| 1.4417 | S31500 | |

| X2 CrNiN 23-4 | 1.4362 | S32304 |

| X3 CrNiMoN 27-5-2 | 1.4460 | S31200 |

| X2 CrNiMoN 21-5-1 | 1.4162 | S32101 |

Chemical analysis | |||||||||

| C | Mn | Si | S | P | Ni | Cr | Mo | Cu | N |

| max. | 0.50 | max. | max. | max. | 7.50 | 21.50 | 2.50 | max. | 0.10 |

| 0.03 | 2.00 | 0.90 | 0.02 | 0.03 | 9.50 | 23.50 | 3.50 | 0.50 | 0.20 |