MIG wire Wurth 59

MIG/MAG nickel-based AWS A5.14: ERNiCrMo-13

WELDWRE-MIG-MIG59-D1,2MM-15KG

Art.-no. 0982923012

EAN 4062856158119

Register and access more than 75 000 products

Nickel-chrome-molybdenum alloy welding wire for nickel-chrome-molybdenum steel alloys with low carbon content, as well as for other nickel-based alloys: duplex, super duplex

Can be used to weld:

- nickel-chrome-molybdenum alloys with low carbon content and chrome-nickel-molybdenum austenitic stainless steels;

- steel that has been coated on one side with nickel-chrome-molybdenum alloy with low carbon content;

- nickel-chrome-molybdenum steel alloy with low carbon content and other nickel-based alloys; duplex, super duplex and super austenitic stainless steels;

Weldable materials: Alloy 22, Alloy 625, Alloy 276, Alloy 686

Procurement product

Classification:

ASME SFA A 5.14: ERNiCrMo-13

EN ISO 18274: G/W Ni 6059 - NiCr23Mo16

BS 2901: Pt 5 NA 48

Material no. 2.4607

Datasheets(X)

Wire diameter (Ø) | 1.2 mm |

Layer-coiled | Yes |

Weight | 15 kg |

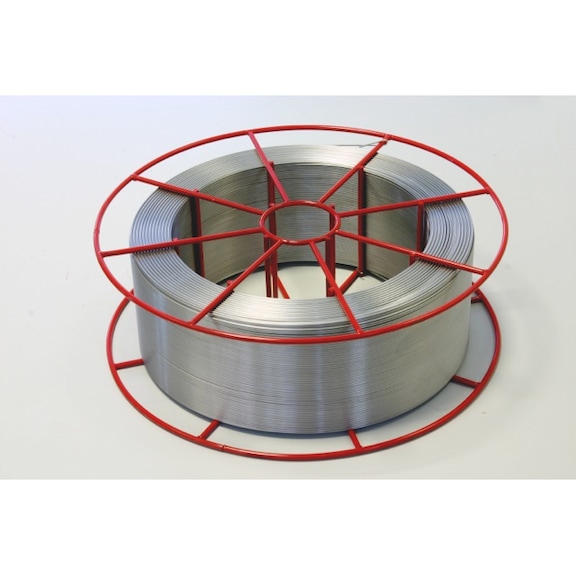

Type of coil | Metal coil BS300, red |

Min. longitudinal elongation | 30 % |

Min. tensile strength | 760 N/mm² |

Product weight (per item) | 15 kg |

American Welding Society (AWS) | A5.14: ERNiCrMo-13 |

Shielding gas | Argon, Argon/Helium |

Mechanical properties, typical, clean welding material | |

| Typical values | |

| Protective gas | I1 |

| 0.2 yield N/mm² | 400 |

| Tensile strength N/mm² | 760 |

| Elongation % | 30 |

| Baton ISO-V(J) +20°C |

Chemical analysis | ||||||||||

| C | Mn | Fe | P | S | Si | Ni | Co | Al | Cr | Mo |

| max | max | max | max | max | max | 56.00 | max | 0.10 | 22.00 | 15.0 |

| 0.010 | 0.50 | 1,50 | 0.020 | 0.005 | 0.08 | min | 0.30 | 0.40 | 24.00 | 16.50 |