For detailed information, other images and documents, please select individual articles from the following table.

Register and access more than 75 000 products

Variants

Register and access more than 75 000 products

Call customer service: 010 308 6700

Prices for customers after login

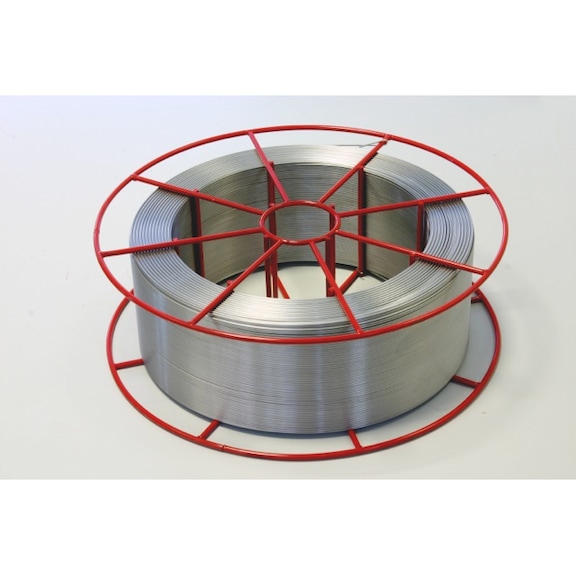

Austenitic ferritic duplex — solid wire made from stainless 22Cr9Ni3Mo steel alloy. The wire has high tensile strength and resistance to cracking caused by pitting corrosion and stress corrosion.

Suitable for welding, combining and coating stainless steels of a similar composition (duplex).

It can be magnetised and polished.

Pitting corrosion index PRE =35.

Weldable materials:

Steel classes EN 10088-1/-2 mat.no./UNS

Duplex stainless steels

- X2 CrNiMoN 22 5 3 1.4462/S31803

- X2 CrNiMoN 22 5 3 1.4417/S31500

- X2 CrNiN 23-4 1.4362/S32304

- X3 CrNiMoN 27-5-2 1.4460/S31200

- X2 CrNiMoN 21 5 1 1.4162/S32101

- AWS A5.9 ER2209

- EN ISO 14343-A G/W 22 9 3 N L

Classification:

AWS A5.9 ER2209

EN ISO 14343-A G/W 22 9 3 N L

Material no. 1.4462

Shielding gases (according to ISO 14175):

M12 Mixed gas Ar+ 0.>5–5% CO2

M13 Mixed gas Ar+ 0.>5–3% O2

- AWS A5.9 ER2209

- EN ISO 14343-A G/W 22 9 3 N L

Applications: Petrochemical and offshore industry (e.g. sheets, piping), where much higher corrosion resistance is required than can be provided by austenitic stainless steel

in environments with high levels of chloride and in temperatures ranging from 50°C–300°C.

Applications: Acid gas industry, transportation of chemical products, applications aimed at reducing contamination, pulp and paper industry.

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!