For detailed information, other images and documents, please select individual articles from the following table.

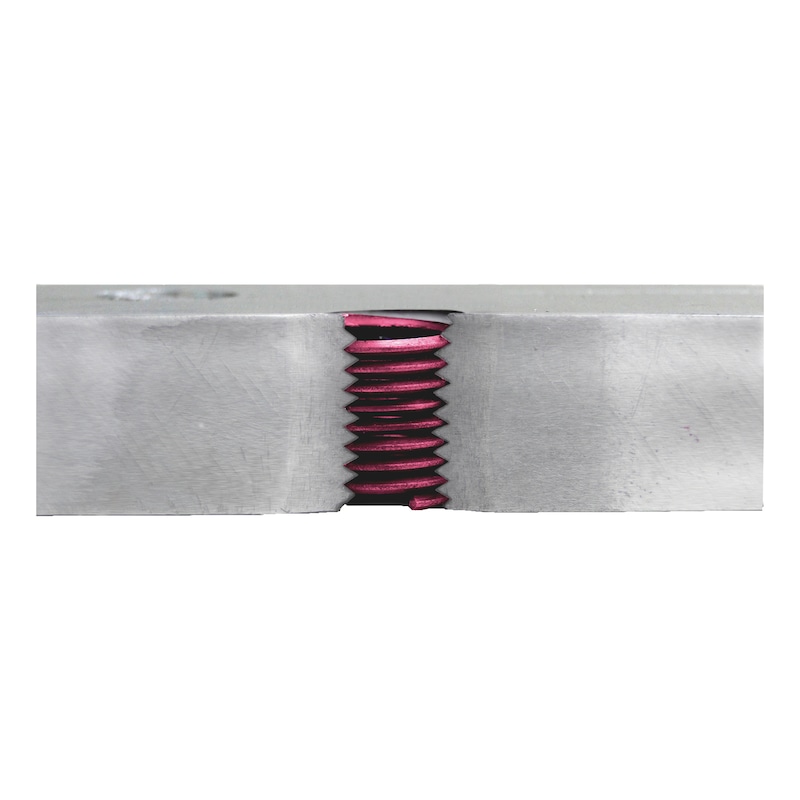

Helical insert W.TEC® INSERT COIL Free Running

For producing a lasting, heavy-duty female thread. With free running, true to gauge thread. Made of A2 stainless steel

Register and access more than 75 000 products

Variants

Register and access more than 75 000 products

Call customer service: 010 308 6700

Prices for customers after login

Perfect combination of space-spacing and wear-resistant thread strength

- In low-strength metal materials

- In plastics

Optimal force distribution

Flexibility of the thread inserts compensates for pitch and angle errors

Thread insert sits securely

Minimised thread friction torque and minimised torsional stress

Increased corrosion resistance

Space and weight minimisation

Smaller number of required connection points and/or reduced screwing dimensions

Costs minimised

By reinforcing the thread, which effectively minimises the repair costs

The tolerance position of the ISO thread corresponds to 6H following installation.

The tolerance position of the ISO thread corresponds to 6H following installation.

A resistant thread in 4 steps:

Step 1:

Drill a core hole or drill out the damaged thread

Step 2:

Create a receiving thread

- By cutting using screw tap

OR

- Without cutting using thread moulding for an even more resilient receiving thread

Step 3:

Set the thread insert

- The helical insert can be mounted both mechanically and also by hand using the corresponding screw-in tool.

Step 4:

Break the pin

- Separate the follower pin by tapping gently on the predetermined break point with a pin breaker, and then remove. Automatic pin breakers are also available for series production.

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!