Screw anchor W-SA

Screw anchor W-SA steel zinc plated type S

ANC-(W-SA/S)-WS24-(A2L)-10-16X80

Register and access more than 75 000 products

- Anchoring by positive locking

- Through-hole mounting

- Immediate load-bearing capacity – no waiting

- Almost no expansion effect, enabling minimal edge and axial clearance to be maintained

- Quick, easy installation or dismantling by screwing the screw anchor in and out of the drill hole

European Technical Approval ETA-05/0012: Option 1 for cracked and non-cracked concrete

Fire resistance (anchoring base: concrete from C20/25 to C50/60): R30, R60, R90, R120: Technical report TR 020 "Evaluation of anchorages in concrete concerning resistance to fire" (included in ETA-05/0012)

W-SA 16x80/10 and W-SA 20x100/10 unapproved

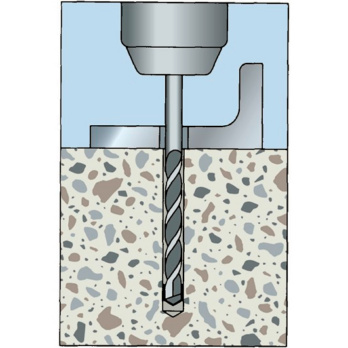

Create the drill hole

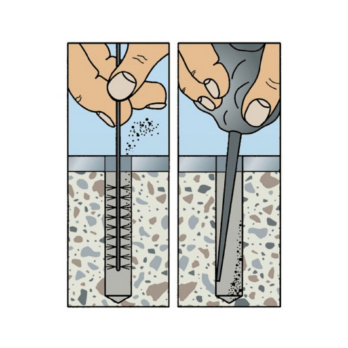

Clean the drill hole

Clean the drill hole

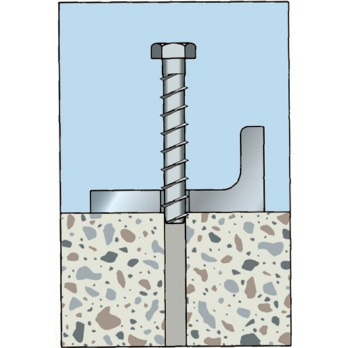

Position anchor

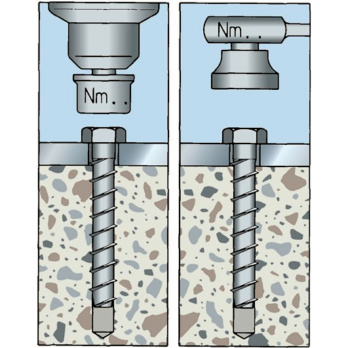

Screw in anchor and apply torque

European Technical Approval ETA-05/0012: Option 1 for cracked and non-cracked concrete

Fire resistance (anchoring base: concrete from C20/25 to C50/60): R30, R60, R90, R120: Technical report TR 020 "Evaluation of anchorages in concrete concerning resistance to fire" (included in ETA-05/0012)

Datasheets(X)

Individual attachment: Cracked and non-cracked concrete

With a European Technical Approval, the anchor may be used in reinforced or non-reinforced standard concrete of a strength class of at least C20/25 and at most C50/60 in accordance with EN 206: 2000-12

The anchor may be used for anchoring with predominantly static loads (e.g. tare weight, fittings, stored materials) or quasi-static loads (e.g. façades, railings)

Can be used in concrete < C 20/25 and hard natural stone (unapproved)

W-SA (galvanised steel) can be used in dry indoor areas

Suitable for attaching metal structures, metal profiles, brackets, footplates, supports, cable conduits, pipes, railings, wooden structures, roof beams, etc.

The saw-tooth threads cut into the concrete when the anchor is screwed into the pre-drilled hole

Head type | Hexagon head |

Nominal drill-bit diameter (d 0) | 14.0 mm |

Surface | Zinc plated |

Through-hole in the component to be connected (d f) | 18.0 mm |

External drive | WS24 |

Material | Steel |

Drive type | Hexagon |

| Performance data | ||||||||

| Anchor diameter [mm] | 7,5 | 10 | 12 | 14 | 16 | 20 6) | ||

| Admissible centric tension load1) on an individual anchor without the influence of the edge distance | Tensile zone (cracked concrete C20/252), s ≥ 3 hef c ≥ 1.5 hef) | Nadm [kN] = C20/25 2) | 2,0 | 3,6 | 4,8 | 7,9 | 11,7 | - |

| Compressive zone (uncracked concrete C20/252), s ≥ 3 hef c ≥ 1.5 hef) | 3,0 | 4,8 | 6,4 | 11,9 | 15,9 | Frec. 11.0 | ||

| Admissible shear load1) on an individual anchor without the influence of the edge distance | Tensile zone (cracked concrete C20/252), c ≥ 10 hef) | Vadm [kN] = C20/25 | 3,3 | 7,6 | 12,4 | 17,1 | 23,3 | - |

| Compressive zone (uncracked concrete C20/252), c ≥ 10 hef) | 3,3 | 7,6 | 12,4 | 17,1 | 23,3 | - | ||

| Admissible bending moment | Madm [Nm] | 9,0 | 18,1 | 39,0 | 62,9 | 103,3 | - | |

| Admissible load when exposed to fire (R30, R60, R90, R120) see European Technical Assessment ETA-05/0012 | ||||||||